VIP Metals engineering CNC Machining

Precision machining for accurate holes, slots, surfaces, and engineered metal features.

Reliable drilling, tapping, reaming, milling, and countersinking with controlled accuracy and consistent finishing for production and custom components.

Engineering CNC-Machining Services

Accurate Cutting. Clean Features. Engineering Grade Precision.

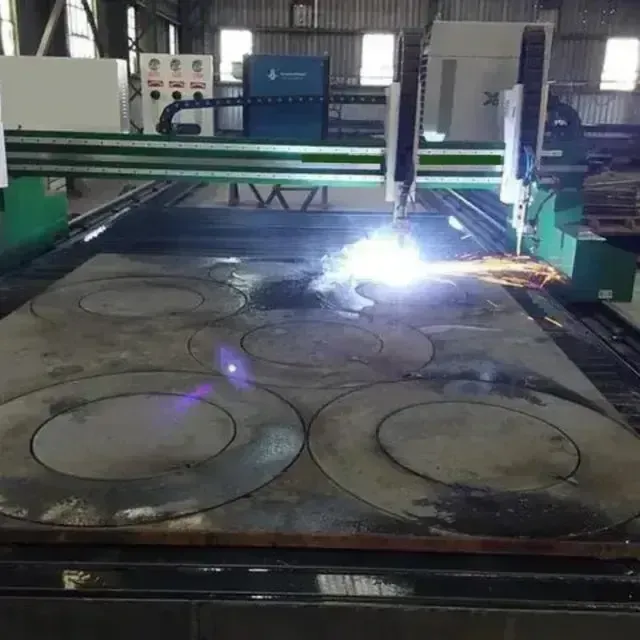

CNC (Computer Numerical Control) machining is a highly automated process that uses programmed tooling to produce engineered components with consistent precision. At VIP Metals, we combine state-of-the-art CNC equipment with rigorous quality control to meet even the most demanding specifications.

We machine a wide range of materials including mild steel, stainless steel, aluminium and other engineering alloys, ensuring each component performs reliably in service. Our capabilities cover drilling, tapping, reaming, 3-axis milling, thread milling and more, tailored to your design requirements

Get a fast quote today and let us machine your components to exact specification.

Ranges of Profiling Services

What Is CNC Machining?

our Engineering CNC Machining services deliver precision-engineered metal components that meet the strict dimensional and quality standards required across industrial and engineering projects. Whether you need a single prototype or high-volume production runs, our CNC machining expertise ensures accuracy, consistency and performance on every part.

Our team uses advanced CNC technology and experienced operators to shape, cut and finish components with

tight tolerances and clean surface finishes. From complex slots and drilled holes to milled profiles and threaded features, we machine parts that integrate seamlessly into larger assemblies or specialised engineering systems.

Why Choose Our CNC-Machining?

High Precision Output

Accurate tool positioning and stable CNC control ensure clean hole placement, detailed edge work, and consistent tolerances across all parts.

Clean and Reliable Finishing

Machined surfaces are produced with controlled feed rates and tooling, resulting in smooth finishes suitable for direct assembly or additional processing.

Efficient Turnaround Times

Machining workflows support urgent jobs, replacement parts, prototypes, and full

production cycles with reliable speed and scheduling.

Versatile Machining Capability

Suitable for drilled parts, tapped features, milled shapes, surface cuts, countersinks, slotted features, and components with complex detailing.

FAQs

Got a question? We’re here to help.

Ready to Experience Precision with VIP Metals?

Let us bring your General Profiling project to life.

Contact VIP Metals today to explore the possibilities, and together, we'll create exceptional solutions tailored to your needs.