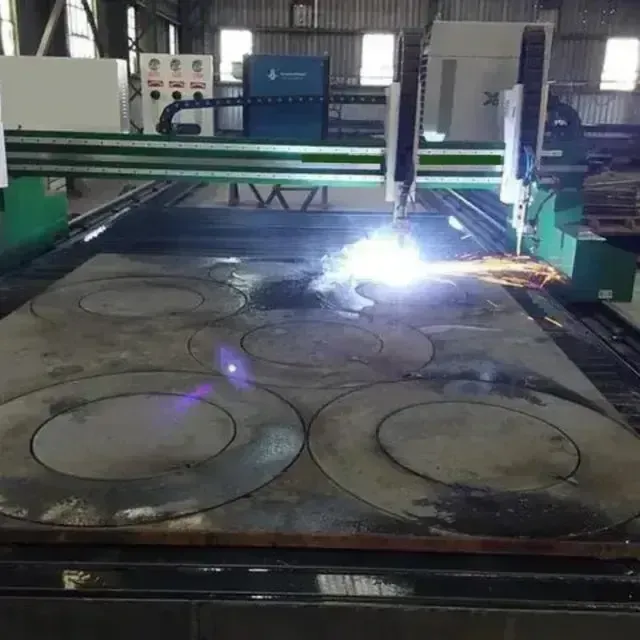

VIP Metals Plasma Cutting

High-performance plasma cutting for accurate profiles, fast processing, and versatile metal applications

Plasma cutting provides efficient profiling across multiple material types with strong edge quality, consistent results, and reliable speed for industrial workflows.

QUALITY | DELIVERY

Plasma Cutting Services

Fast Processing. Strong Edge Quality. Reliable Performance.

our Plasma Cutting service combines high-performance CNC technology with industrial reliability to deliver fast, accurate and versatile metal profiling for a wide range of applications. Whether you require components for structural fabrication, engineered assemblies or general manufacturing, our plasma cutting capability is designed for consistent quality, dependable capacity and on-time delivery.

Our CNC plasma cutting system is built to handle large-format plates up to 12 000 mm × 3 500 mm, with cutting thicknesses ranging from 10 mm to 50 mm. This allows us to process both intricate profiles and heavy industrial components efficiently, while maintaining accuracy across single parts or repeat production runs.

Plasma cutting is a CNC-controlled process that uses a high-energy plasma arc to cut electrically conductive metals with precision and speed. At VIP Metals, we cut a wide range of materials including mild steel, VRN, Hardox, stainless steel and aluminium, producing clean edges, minimal heat distortion and reliable dimensional accuracy. This makes plasma cutting an ideal solution for medium-thickness plates where speed, quality and versatility are essential.

Get a fast quote today and let us cut your components to exact specifications.

Ranges of Profiling Services

What Is Plasma Cutting?

Plasma cutting is a high-speed industrial process that uses ionised gas to cut

electrically conductive metals with accuracy and efficiency. Guided by CNC motion control, it produces clean edges and reliable results across a wide range of plate sizes and thicknesses. This cutting method is ideal for structural work, fabrication projects, engineered components, and general manufacturing, where a balance of speed and cut quality is essential.

Why Choose Our Plasma Cutting?

Fast Cutting Speeds

Plasma cutting delivers rapid profiling, which makes it ideal for production environments and urgent projects that require efficient turnaround.

Versatile Metal Processing

Cuts multiple metal types and varying thicknesses while maintaining stable cut quality on both small parts and large profiles.

Reliable Industrial Results

Produces clean, consistent edges that are suitable for welding, machining, and

fabrication processes in demanding environments.

Cost Effective for Many Applications

Provides strong cutting performance at competitive operating costs, which makes it a practical choice for general fabrication and engineering work.

FAQs

Got a question? We’re here to help.

Ready to Experience Precision with VIP Metals?

Let us bring your General Profiling project to life.

Contact VIP Metals today to explore the possibilities, and together, we'll create exceptional solutions tailored to your needs.