Department of Water and Sanitation Project Data

Doorn Draai Blank Flange Project

Technical Report: Isolation Flanges for Main Water Line Maintenance

Purpose

This report documents the fabrication, inspection, and testing of DN900 and DN600 blank flanges installed to facilitate the isolation of the main water supply line leading to the purification plant. The isolation was required to enable safe maintenance activities on the existing pipeline system.

Scope of Work

The scope included:

- Fabrication of DN900 and DN600 blank flanges.

- Machining and surface preparation as per design requirements.

- Hydrostatic testing of the DN900 flange.

- Verification of material certification and compliance with relevant standards.

- Installation readiness inspection prior to use in the isolation procedure.

Fabrication Details

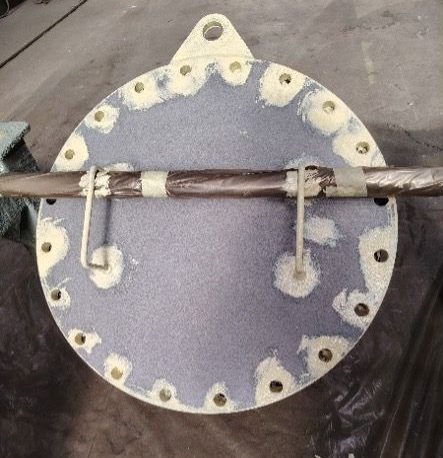

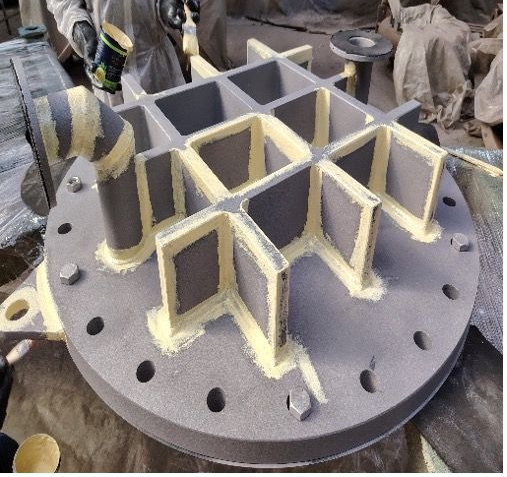

DN900 Blank Flange

- Standard of Manufacture: In accordance with relevant British Standards (BS) for flanges and pressure-retaining components.

- Material: Carbon steel (grade per BS specifications; verified by material test certificate).

- Testing: Subjected to hydrostatic pressure testing to confirm structural integrity and pressure-tightness. The flange passed the test with no visible deformation or leakage.

- Finish: Machined to achieve the required sealing face finish suitable for gasket installation.

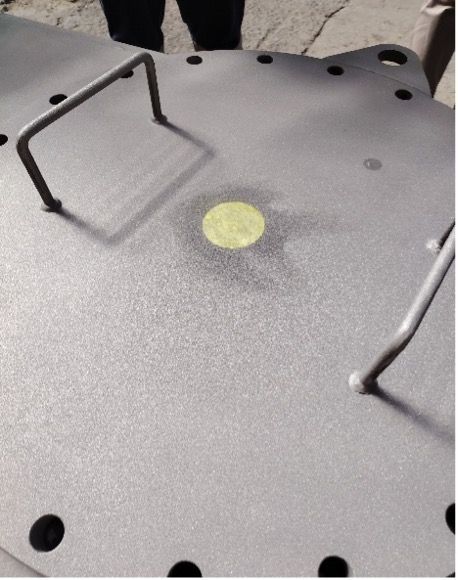

DN600 Blank Flange

- Material: Fabricated from S355JR+AR structural steel plate, in compliance with EN 10025-2.

- Manufacturing Process: The flange was profile-cut and machined to specification.

- Face Finish: Machined to a Phonographic Finish N11, providing the required spiral-groove sealing surface in accordance with BS EN ISO 8503-2.

- Inspection: Visual inspection confirmed dimensional accuracy, smooth surface finish, and absence of surface defects.

Compliance and Documentation

- All materials were accompanied by Mill Test Certificates (MTCs) confirming compliance with relevant BS and EN standards.

- All fabrication and testing activities were carried out under approved QA/QC procedures.

- Hydrostatic test records and inspection reports are attached as Appendices A–C.

Both the DN900 and DN600 blank flanges were fabricated, machined, and inspected in accordance with applicable British Standards and project specifications. Testing confirmed full compliance with pressure and sealing requirements. The components were deemed fit for installation and used to safely isolate the main water line for maintenance operations

DN900

DN600